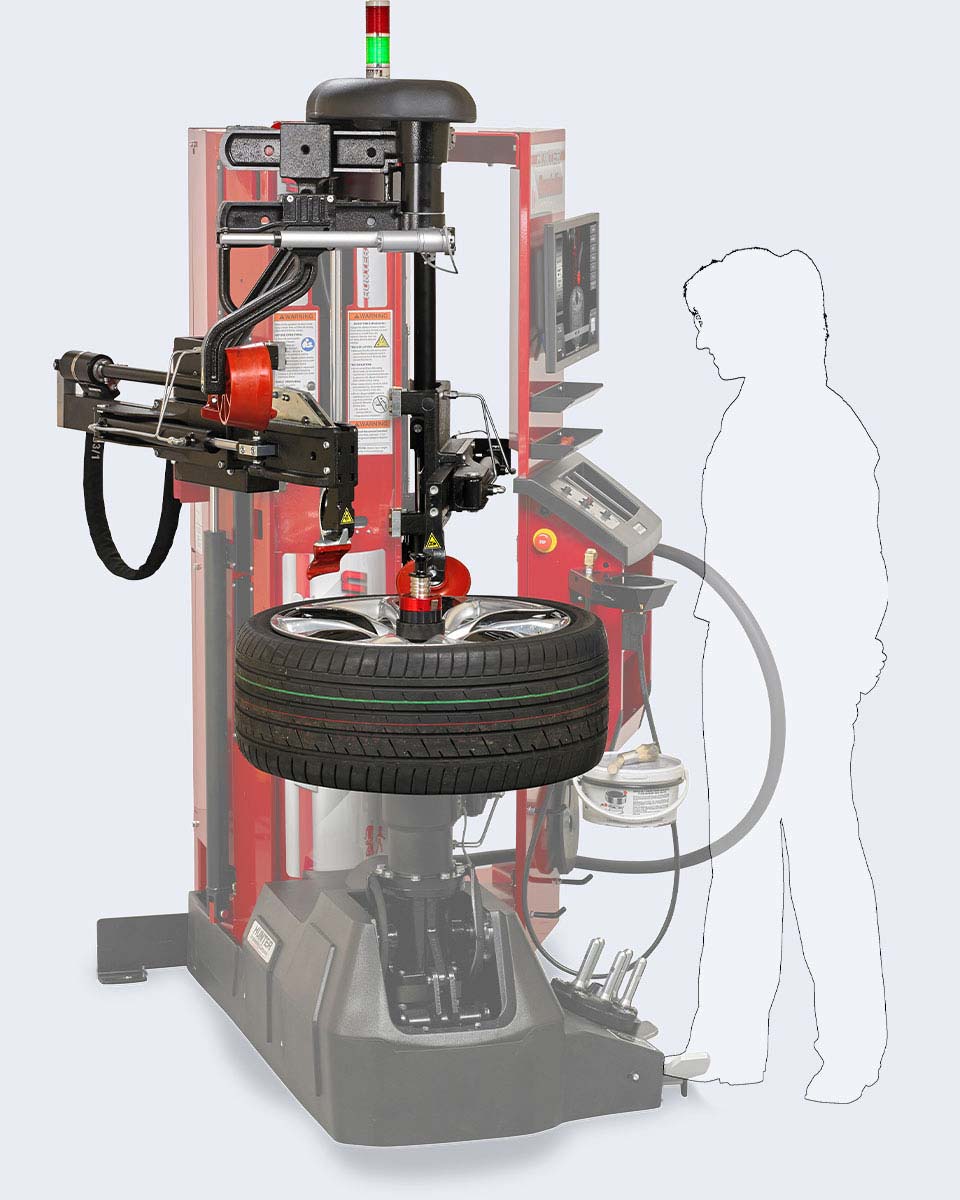

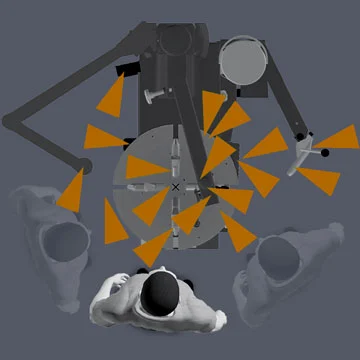

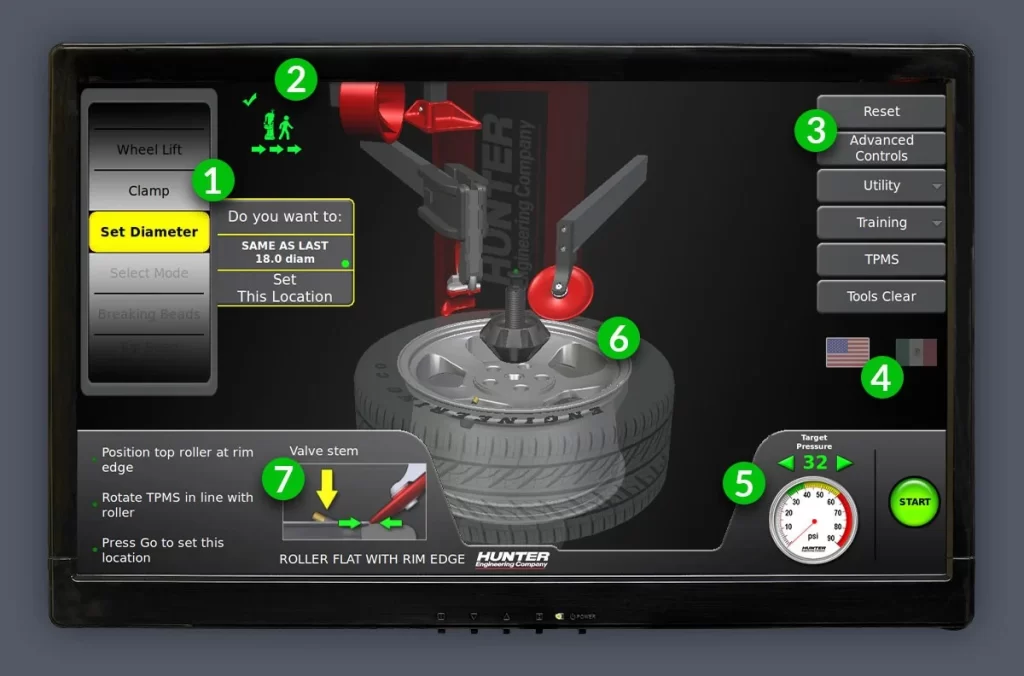

A status indicator light signals when the Revolution™ is operating autonomously, or when the technician is needed.

- Steady green – Revolution is running autonomously

- Flashing green – Autonomous task is complete

- Steady red – Operator required

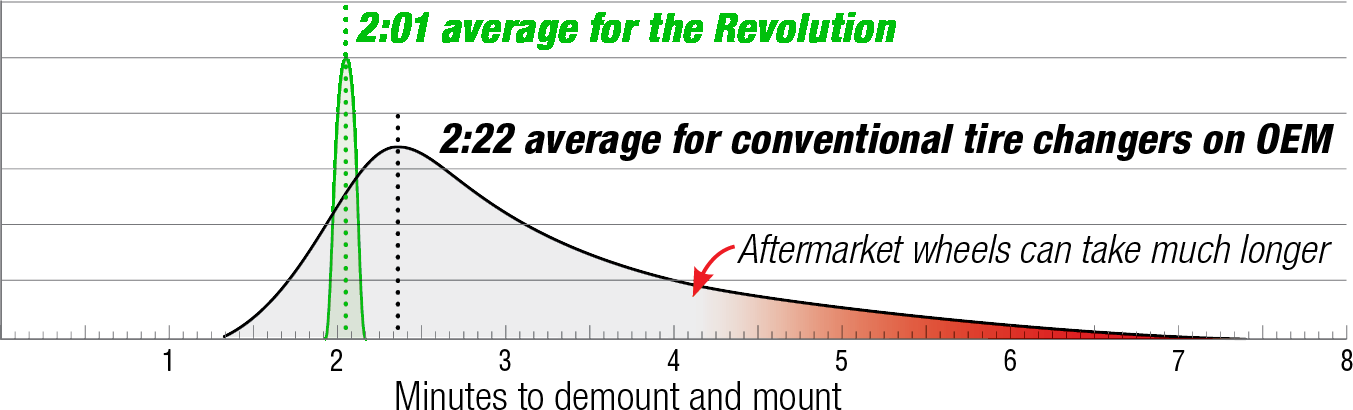

Walkaway time savings

possible for 4 tire set

Minute service time

typical for ALL tire and wheel types

Fewer Decisions

Manual tire changers demand constant decision making

When paired with wheel balancing, a four tire changeover time can be cut by 25% or more!

Mount & Clamp

Technician-performed

Bead-Breaking

WalkAway™ function

Demounting

WalkAway™ function

Mounting

Technician-performed

A status indicator light signals when the Revolution™ is operating autonomously, or when the technician is needed.

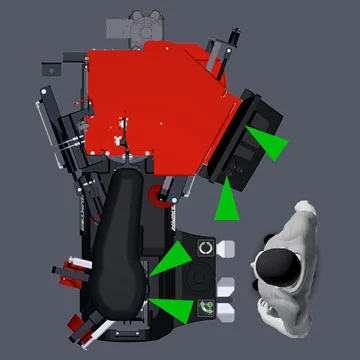

Leverless hook and floating mount head system work together to eliminate rim damage

Hunter’s patented press arm system can be used for every tire with no time penalty. Ensure all tires are mounted properly the first time.

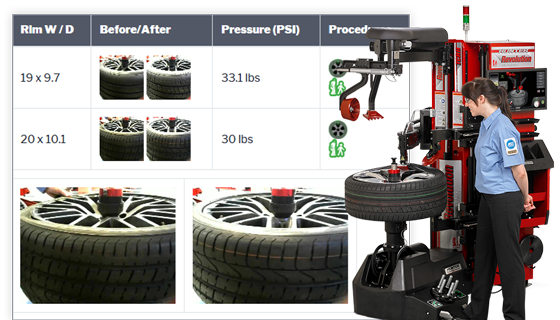

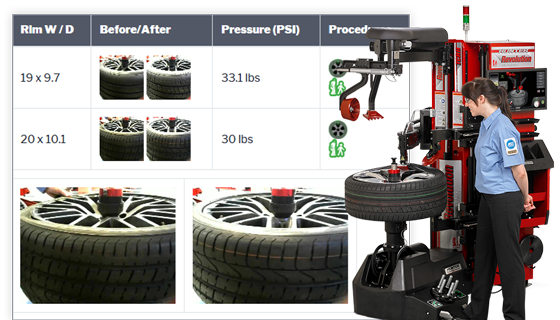

HunterNet® 2 shows your tire changer results, pressures set, procedures used, before and after photos, and more.

“We were looking to get into tire changing and balancing, but needed the easiest machines to operate. We do a ton of custom sized wheels, and this machine can do it all with ease.”

Autotronica – Anaheim, CA

Fully-automatic keeps operators hands and body safely away from the machine. Wheel lift protects operator’s back.

Automatic procedure protects expensive rims and tires. Polymer tools ensure scratch free operation.

Machine constantly monitors TPMS location. Automatically mounts and demounts with best TPMS procedures.

No levers to hit operator.

Automatic press arms replace using levers for mounting

Protect your investment and verify your work with camera-recorded processes.

Monitors TPMS location constantly.

Won’t allow tire to be mounted or demounted in unsafe TPMS location

Inflation station algorithm fills to set pressure automatically - not necessary to stand on foot pedal to inflate.

Inflation controls keep operator away from assembly

Operator’s hands stay away from the assembly.

No pinch points.

No risk of rim slipping

Automatic procedure protects rim and tire.

Protects operator’s back.

No need to lift heavy assemblies

Operator stands back and lets the machine do the work

HunterNet® 2 allows you to re-order consumable items to keep your technicians and equipment running without interruptions.

Everyone on your tire changing team can be equally productive with simple, automatic operation.

On conventional tire machines, equipment is the tool and the technician is the tire changer.

The Revolution™ is the tire changer and the technician is an equipment operator.

With manual tire changing, the technicians is constantly making critical decisions to successfully change a tire without damaging the wheel, the tire, the TPMS sensor, or even themselves.

The Revolution™ only requires four key decisions from the operator. New techs are productive faster and everyone works smarter.

17 critical decisions for conventional tire changers

4 critical decisions for the Revolution™

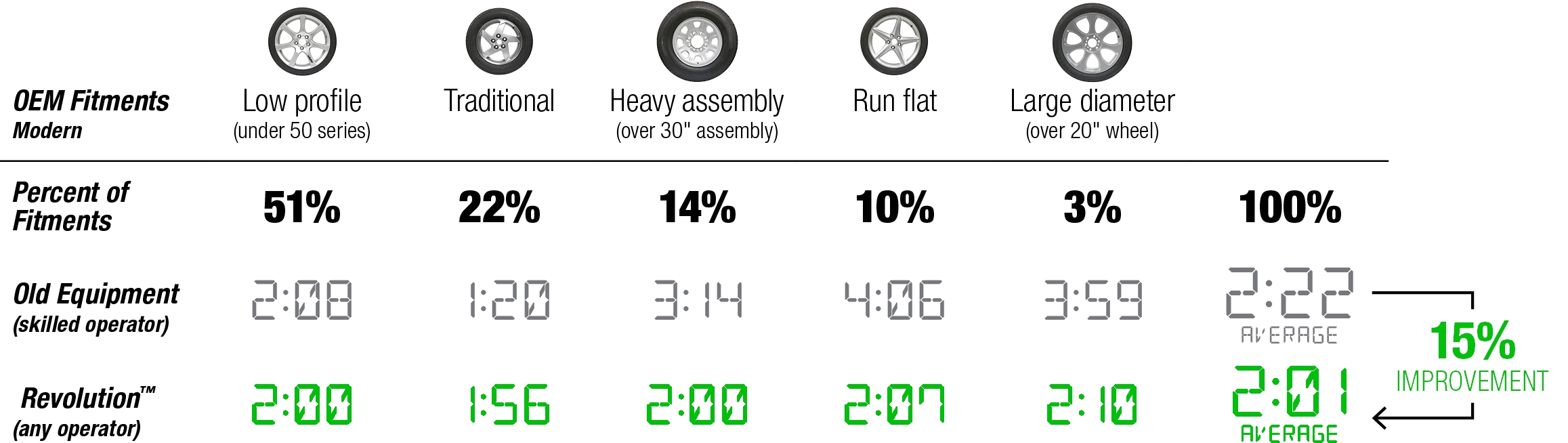

The same process for all tires means all tires take the same time. Don't allow efficiency to leak away with run flats or other difficult tires.

Time to service today's tires can be 15% faster, because tough tires don't phase the Revolution™. Add in Walkaway™ autonomous operation, and no tire changer is faster.

“My favorite thing about the Revolution™ tire machine is I don’t have to physically bend over and pick up the tires. It’s about a 10-15 minute difference doing it on the manual machine as opposed to this. Watch me do one tire, that’s all you need.“

Eddy’s Toyota – Wichita, KS

Provide animated guidance for new users. The entire tire changing process is shown on screen to easily see what’s ahead.

24 videos available to guide a technician through accessory or special procedures.

The Revolution™ can toggle between any 2 of 28 languages, on the fly.

Protect your investment by proving preexisting rim damage or incorrect operation.

See how Revolution™ Walkaway™ accelerates the four tire changeover

Quick highlights of Revolution™ benefits

Don’t believe the Revolution™ is an equalizer, watch this!

Original long format introduction video of Revolution™

Performance TV films Revolution™ at SEMA 2015

Mr JWW’s McLaren Serviced in UK.

Two Guys Garage film Revolution™

| Key Specifications | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clamping Type | Center w/Quick Clamp and Cam Plate | ||||||||||||||||||||||||||||

| Mount/Demount Tool | Polymer Self Inserting Leverless | ||||||||||||||||||||||||||||

| Bead Loosening Type | Upper/Lower Roller | ||||||||||||||||||||||||||||

| Match Mounting Capable | YES | ||||||||||||||||||||||||||||

| Rim Diameter Range (Min) | 12in | ||||||||||||||||||||||||||||

| Rim Diameter Range (Max) | 30in | ||||||||||||||||||||||||||||

| Max Tire Diameter | 50in | ||||||||||||||||||||||||||||

| Max Wheel Width | 15in | ||||||||||||||||||||||||||||

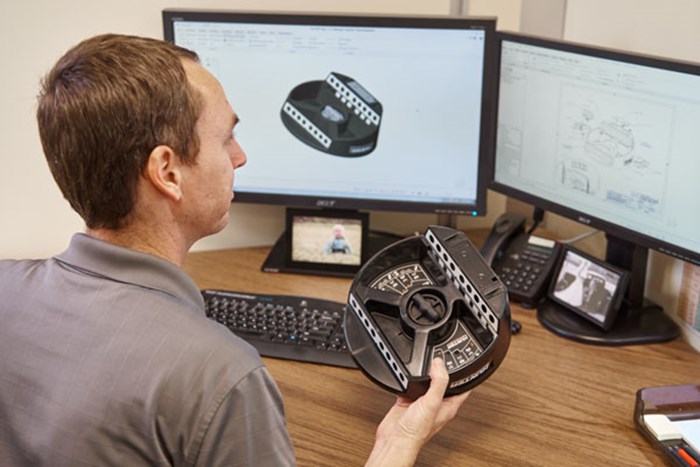

Family owned, goal-driven

Expert assembly goes into each alignment system, alignment console, tire changer, balancer, brake lathe and other components.

Largest in the industry

Hunter deploys the largest service force of highly-qualified representatives in the industry.

Award-Winning

Hundreds of patented and exclusive features begin with the research and development team of mechanical, electrical and software engineers.

Smith Garage Equipment is a leading garage equipment distributor for automotive repair equipment and heavy duty equipment.

© 2024 Smith Garage • All Rights Reserved