Provide a smooth, precise brake finish directly on the vehicle. Hunter’s AutoComp Elite® on-car brake lathe is a cut above the rest.

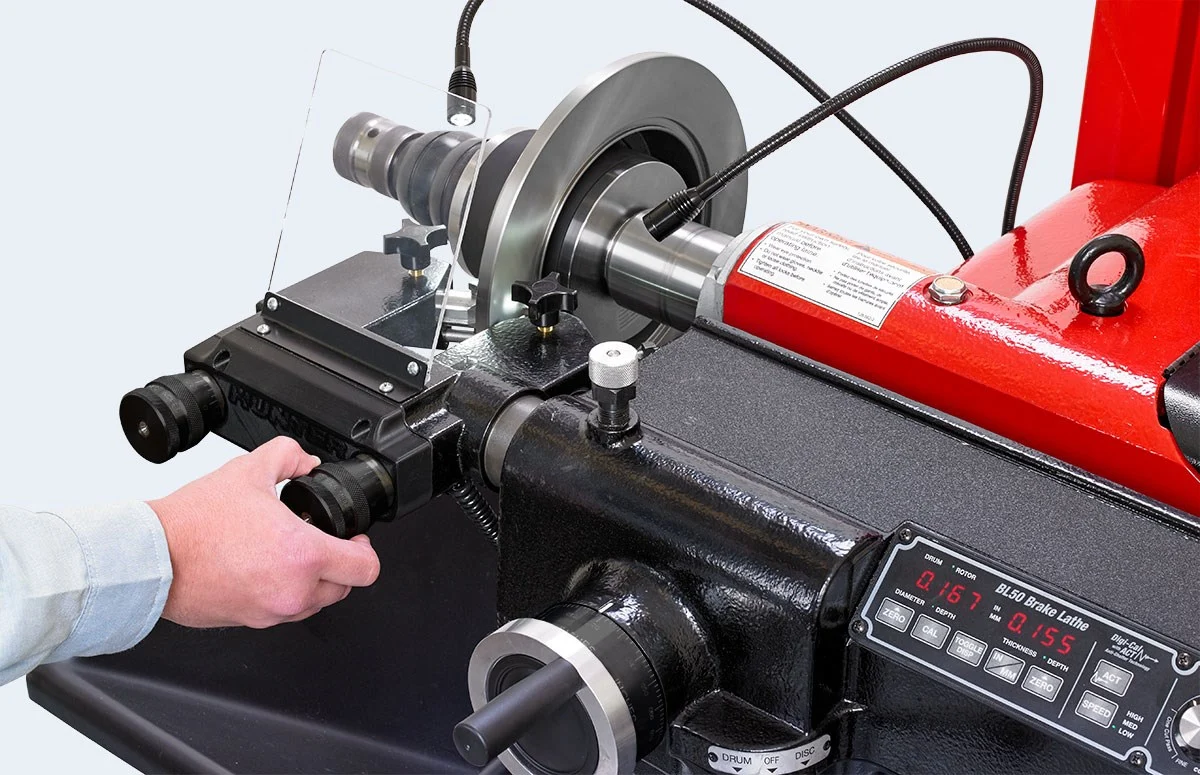

BL Series Bench Lathe

Same industry leading design, now with new optional features

Previous

Next

BL Series Bench Lathe

Industry leading combination bench lathe

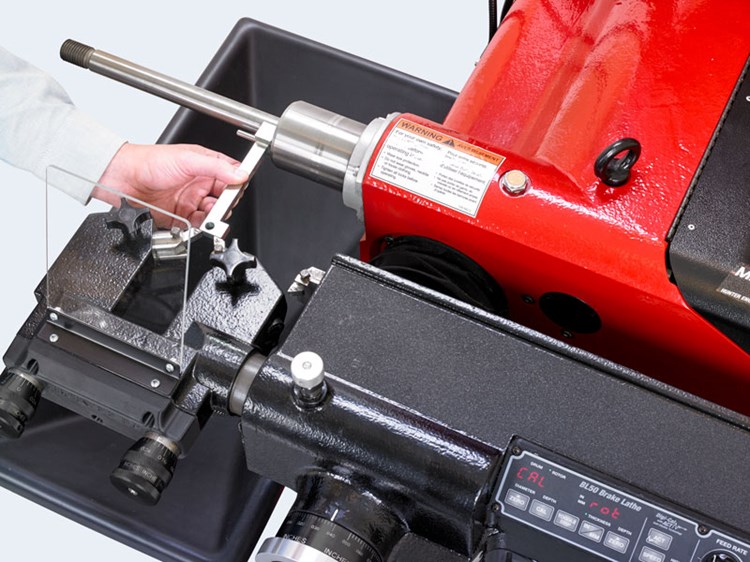

The BL Series Bench Lathe is a combination bench lathe that brings speed, precision and versatility to your brake service. The unique design of this combination lathe allows the operator to change the setup of the brake lathe from rotors to drums and vice versa with unprecedented speed and ease. Building on the same industry leading design of our previous bench lathe, the new BL Series Bench Lathe now has optional new features!

Features at-a-glance

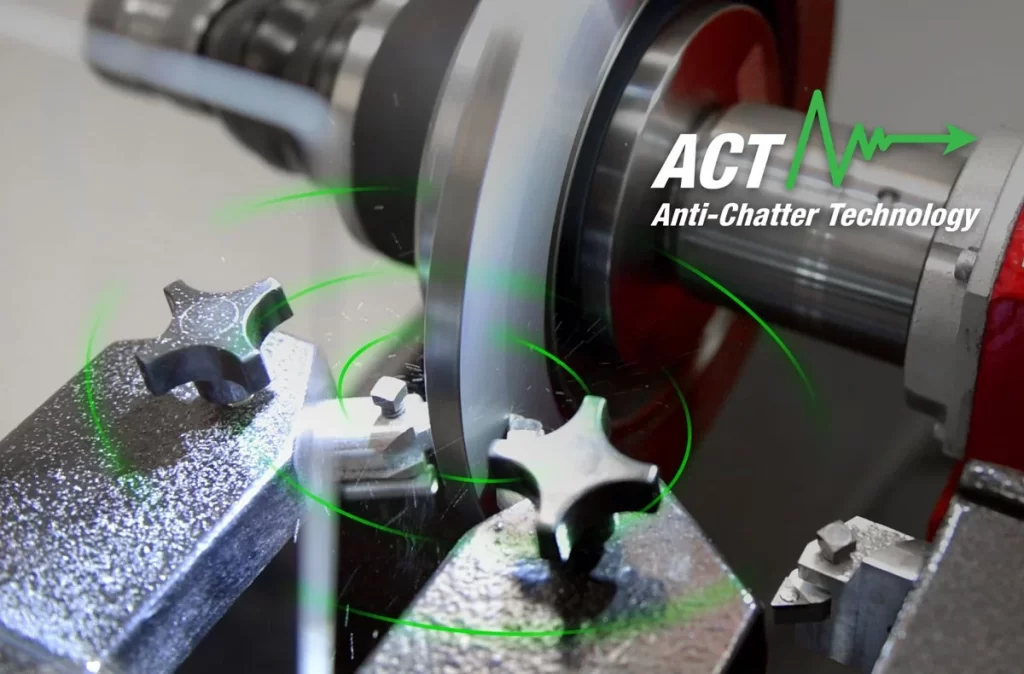

New Anti-Chatter Technology option

New Digi-Cal option

Adjustable spindle speed

Adjustable feed rate

Specifications at-a-glance

6 - 22 in.

Rotor diameter

6 - 24 in.

Drum Diameter

1.5 hp

Motor power (optional)

200 lbs

Maximum arbor weight

See them in action

Playlist

4 Videos

Descripción

Laura Ford in Sullivan, MO uses Hunter’s AutoComp Elite® On-Car Brake Lathe to help service a wide variety of vehicles at their dealership. They’ve tried other on-car lathes in the past, but chose the ACE Lathe for easier setup, faster automatic compensation, faster cutting, and its superior surface finish.

Descripción

The AutoComp Elite® brake lathe features automatic compensation technology. The patent pending automatic compensation system directly determines the position of the internal plates to maximize speed and accuracy without operator intervention. The result is the fastest, highest quality brake job possible.

Descripción

An in-depth explination on how Hunter Engineering’s Anti-Chatter Technology (ACT) works on Hunter’s BL Series Bench Lathe and the on-car lathe, AutoComp Elite®. This technology provides better brake rotor surface finish while also allowing the lathe to cut much faster.

Descripción

This video explores the causes of vehicle brake shudder and explains why resurfacing rotors on the vehicle provides a better, longer lasting brake job.

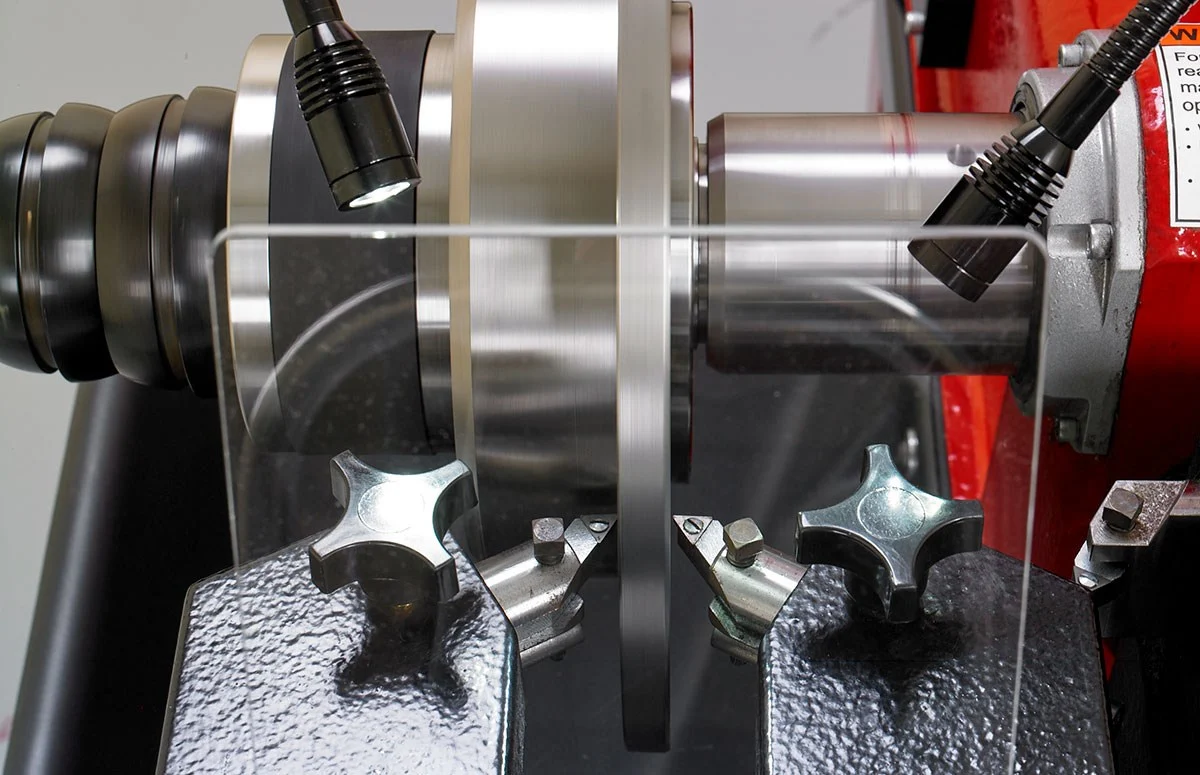

Optional Anti-Chatter Technology

Smooth finish with Anti-Chatter Technology

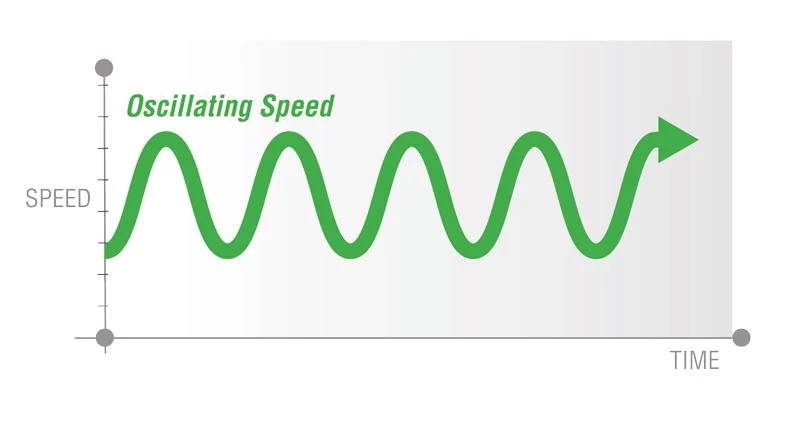

Anti-Chatter Technology changes the spindle speed to keep chatter-inducing vibration from starting

Eliminate the need for silencer bands

No hazardous bands, clips or silencer belts needed to control vibration

Eliminate virtually all buildup of vibration to stop chatter before it starts!

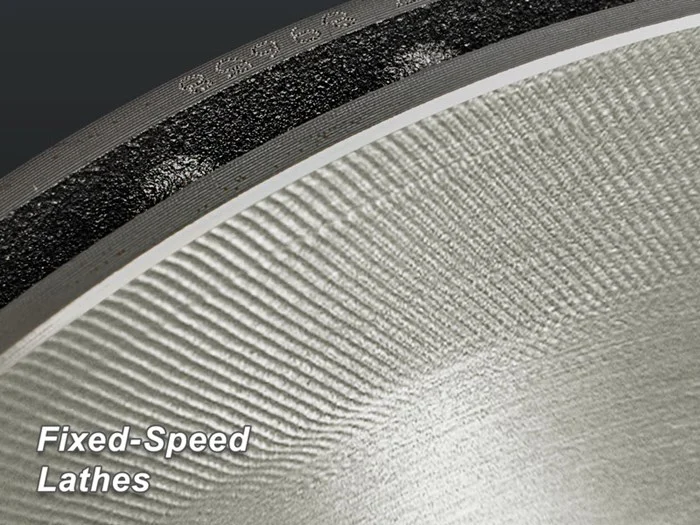

Other Lathes

Fixed-speed

Chatter can start when machining rotors at a fixed speed. The same way a moistened finger can make a crystal glass sing. By the time the technician hears the rotor singing, it is already too late; the surface has been ruined.

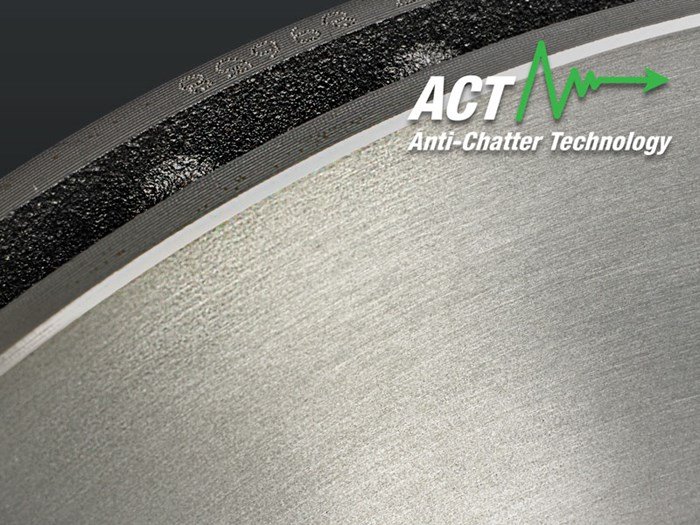

ACT Anti-Chatter Technology

Oscillating speed

ACT varies the spinning speed to keep chatter inducing vibration from starting. This results in a smoother surface finish.

Work in a more efficient space with easy access to tools & adaptors

OPTIONAL

Dust containment system

Protect air quality with the ability to view the work piece during machining.

FEATURE

Pegboard hangers

Store frequently-used adaptors within easy reach.

FEATURE

Twin work lamps

Adjustable LED lights illuminate both side of workpiece

OPTIONAL

Anti-Chatter Control

Variable spindle speed keeps chatter-inducing vibration from starting, making a smooth finish.

OPTIONAL

DigiCal measurement

Instantly measure drum or rotor dimensions and depth of cut.

FEATURE

Large chip collection funnel

Prevent debris from falling to the floor.

STANDARD

Storage drawer

Allow expansion of tool and accessory storage. Easily bolts in place.

FEATURE

Document holder

Store operation manual, application charts and other reference materials.

Adjustable feed rate

Dial in adjustable feed rate for faster, rapid removal to a slower, final surface finish. Allows technicians to cut rotors in one pass.

Push-Button Speed Control

Optional Digi-Cal uses pushbutton speed control to instantly measure and display dimensions for quick calibration and greater accuracy

Calibration in seconds

The calibration procedure for drums and rotors takes seconds, helping to prevent accidental removal of excess material

Measure rotor thickness

Optional DigiCal determines if the piece should be discarded prior to cutting..

Adjustable feed rate

Dial in adjustable feed rate for faster, rapid removal to a slower, final surface finish. Allows technicians to cut rotors in one pass.

Push-Button Speed Control

Optional Digi-Cal uses pushbutton speed control to instantly measure and display dimensions for quick calibration and greater accuracy

Calibration in seconds

The calibration procedure for drums and rotors takes seconds, helping to prevent accidental removal of excess material

Measure rotor thickness

Optional DigiCal determines if the piece should be discarded prior to cutting..

Push button controls

Quickly change spindle speeds with the push of a button

ASwitch from rotors to drums

Changing from rotors to drums takes seconds and is the fastest in the industry, greatly reducing setup time

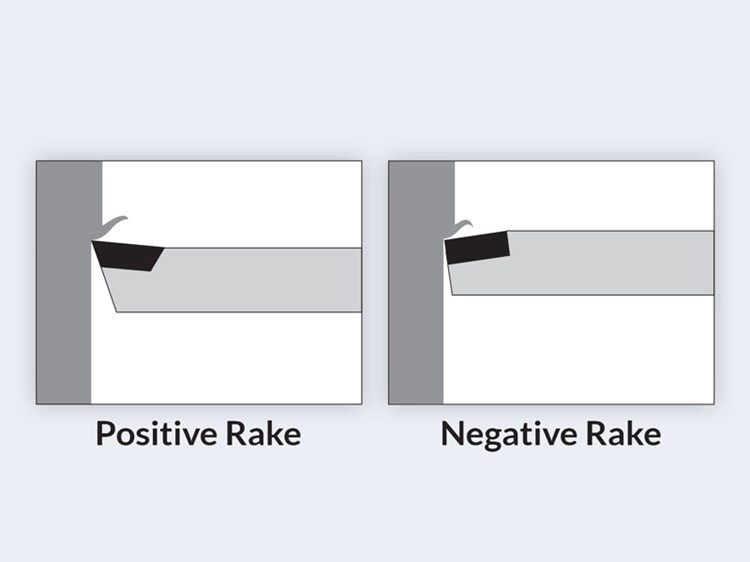

Choice of lathe tooling

Faster-cutting and reduced-chatter positive rake standard (3 cutting tips). Durable, longer-life negative rake (optionl) tooling available (6 cutting tips)

Optional storage configurations

Store frequently-used adpators within easy reach with the optional heavy gauge, all-steel bench option with rear backboard

Optional self-aligning nut

Speeds setup & prevents overtightening and mounting errors

Push button controls

Quickly change spindle speeds with the push of a button

ASwitch from rotors to drums

Changing from rotors to drums takes seconds and is the fastest in the industry, greatly reducing setup time

Choice of lathe tooling

Faster-cutting and reduced-chatter positive rake standard (3 cutting tips). Durable, longer-life negative rake (optionl) tooling available (6 cutting tips)

Optional storage configurations

Store frequently-used adpators within easy reach with the optional heavy gauge, all-steel bench option with rear backboard

Optional self-aligning nut

Speeds setup & prevents overtightening and mounting errors

Specifications

Comparison Table

Rotor

Diameter

22in*

Maximum width

5-3/8in

Maximum thickness

2in

Drum

Diameter

24in*

Maximum width

8in

Additional Information

Power

115/230 V, 15/7.5 amp, 50/60 Hz, 1ph

Maximum weight on 1 in. arbor

200 lbs.

Spindle speed(s)

85, 110, 175 rpm

Get a free pricing quote today!

Explore further

AutoComp Elite®

On-Car Brake Lathe

Service rotors directly on the car for a quick, quality brake job

Designed & Built in the USA

Family owned, goal-driven

Expert assembly goes into each alignment system, alignment console, tire changer, balancer, brake lathe and other components.

Hunter service

Largest in the industry

Hunter deploys the largest service force of highly-qualified representatives in the industry.