Receive daily Push Reports that measure your performance in real time, maximizing your return on investment.

Quick Check® Unmanned Inspection

Scan

every vehicle No stopping required

5x

Alignment opportunities

3D

tire results Help sell critical replacements

Playlist

Unmanned drive-through alignment and tread inspection in 15 seconds.

Joe Schlueter, Morgan Auto Group’s VP of Fixed Operations, talks about the technological advantages and increased sales generated by Hunter’s Quick Check Drive® and Quick Tread Edge® at Jerry Ulm Chrysler Dodge Jeep Ram.

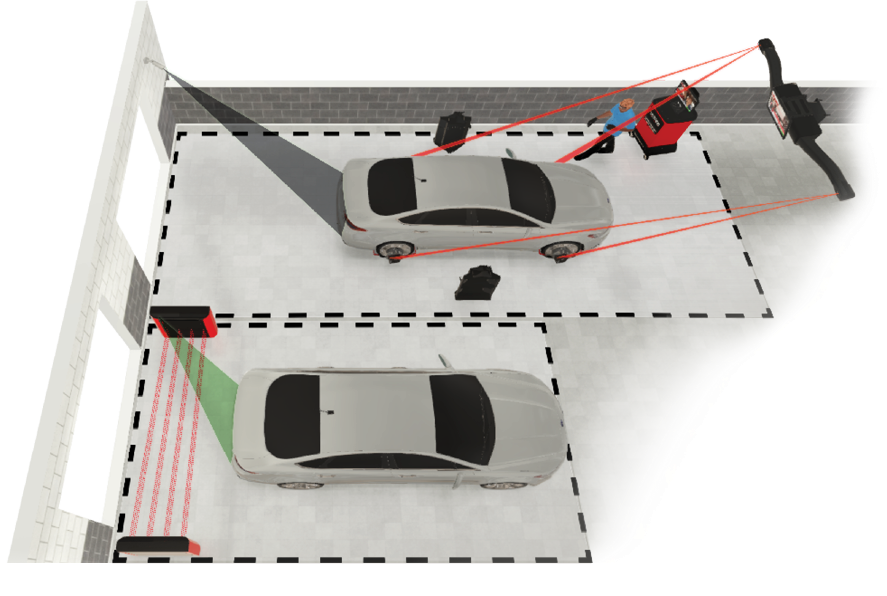

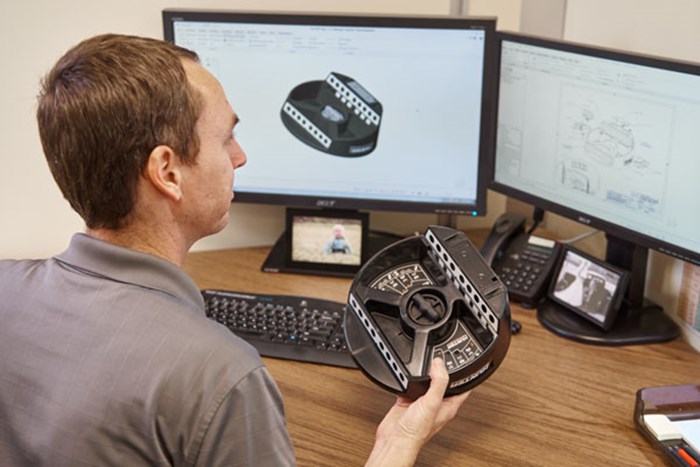

Hunter Engineering Company’s Quick Check Drive® system provides autonomous alignment audits powered by Hunter’s award-winning WinAlign® software. Using 32 lasers and 8 cameras, the completely unmanned system scans a vehicle’s wheels as they drive through without stopping.

Mark Rhodes, President of Plaza Tire Service®, has invested in Quick Check Drive® and Quick Tread Edge® systems at all of the new Plaza Tire locations being built and has the goal of putting the inspection system in each of Plaza’s 67 locations.

Service Director of Suntrup Automotive Group, Elliot Silk, explains why Quick Check Drive® was the best investment made to help sales, retention and overall customer experience at Suntrup Kia South.

Hunter Engineering Company’s Quick Check Drive® system provides autonomous alignment audits powered by Hunter’s award-winning WinAlign® software. The completely unmanned system uses patented measurement technology to scan a vehicle as it drives through without stopping and provides total toe and individual camber measurements in seconds.

Eddy’s Toyota in Wichita, Kansas installed Quick Check Drive® automated alignment inspection systems in their service drives and saw an immediate return on investment, increasing their alignment sales by 300%!

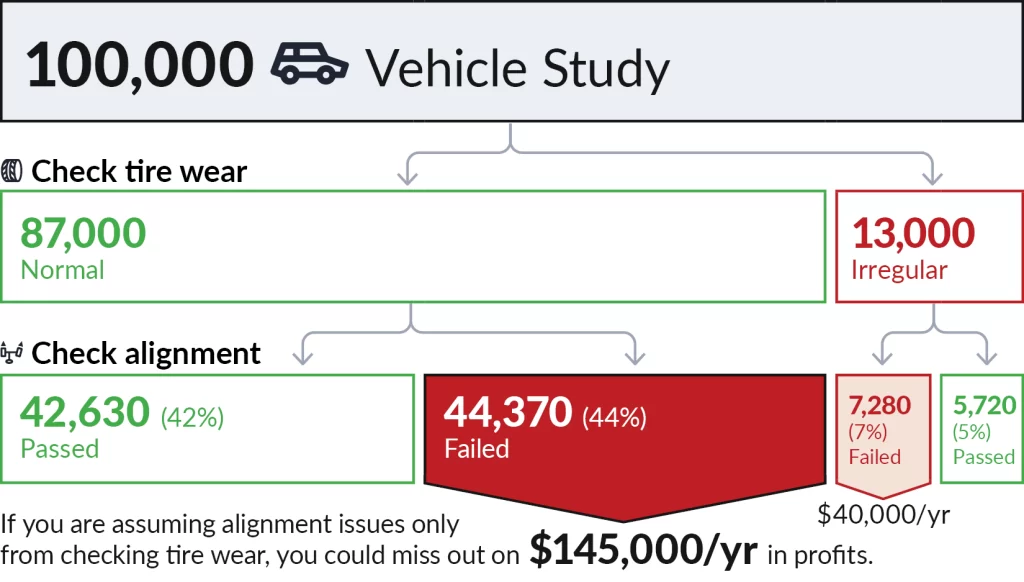

Don't lose out on hidden alignment opportunities

Tire wear alone cannot predict wheel alignment

In a 100,000 vehicle study, irregular tire wear is present only 13% of the time. If you check only tire wear and base your alignment assumptions on that, you are missing a wealth of opportunities from vehicles that are out-of-alignment but show regular tire wear.

Quick Check® Drive checks every vehicle's alignment.

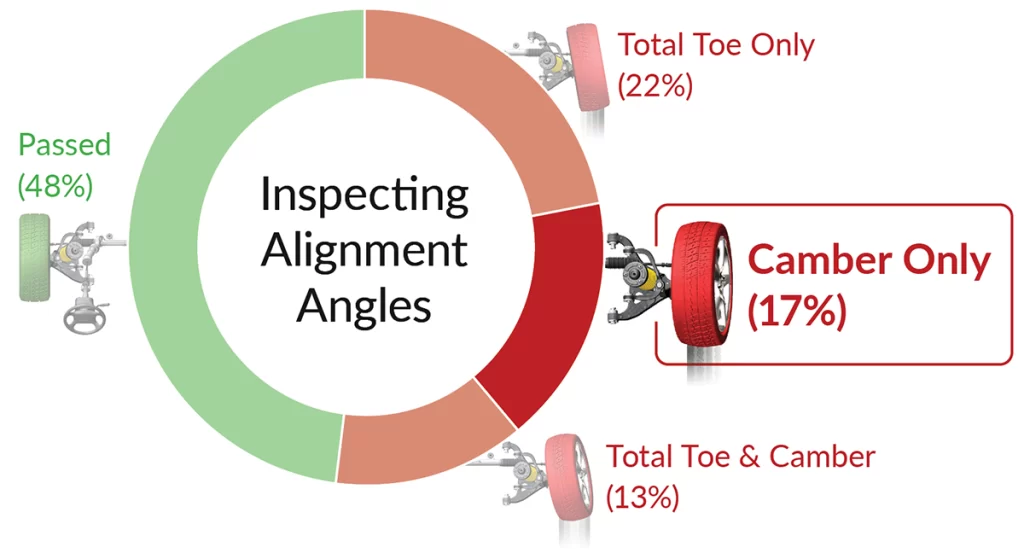

If you're not checking camber, you're missing out on profitable services

Unlike Quick Check® Drive, many systems do not measure camber. Vehicles with only camber out would likely pass other systems' inspections, letting opportunities and profits go out the door.

Quick Check® Drive checks every vehicle's camber.

Automatic results

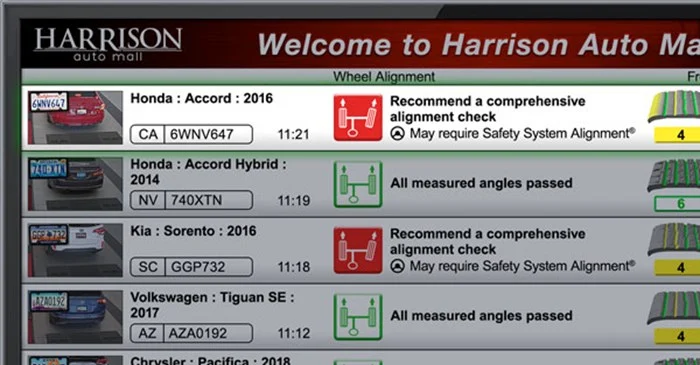

Provide complete customer transparency with Flightboard™ results display

Results visible to all

Customer vehicle results display automatically in waiting area or service drive

Go beyond paper results

Digital presentation helps inform customer before reviewing with technician or service writer

Hunter’s Flightboard™ digital display results offer complete transparency for your customers.

Printouts are still a tangible selling tool

Hands-on customer interaction

Results in seconds

Build a layout that is unique to your business

Select the format with the highest impact for your customers

Automatic results

Streamline your intake process with touchless & efficient design

Eliminate trips around the car

Unmanned solution means faster scans with no labor

Capture data with unmatched accuracy

Eight cameras and 32 lasers produce results with world-class precision

Reduce your intake lane footprint

Requires 25-50% less bay space than other inspection units

No stopping

No labor

No data entry

Track your performance day to day

Set goals, track daily performance, and identify business trends in real time with HunterNet® 2.

Innovative technology

Patented, autonomous technology in powerful, compact units

Ready when you are

Scan a vehicle every 3 to 5 seconds, only activating when a vehicle is present.

Extensive OEM support

Backed by Hunter's superior OEM specification database, pass/fail results are more accurate, saving time and avoiding comebacks

High-definition cameras

Automatically identify vehicles based on registered license plates. Add full-vehicle image capture of 40+ photos to prevent false damage claims (optional).

Accurate alignment results

Optical and laser sensors accurately measure camber and total toe by taking 16 measurements per tire. Results are repeatable.

Automatic tire tread measurement

Scan each tire edge-to-edge and provide accurate 3D models to help sell replacement opportunities.

OEM approvals

Approved & recommended by multiple OEM partners

Automatic vehicle identification

Quickly identify every vehicle through built-in, automatic cameras

Quickly identify vehicles

Automatically determines specs on most vehicles.

Built-in cameras

High-resolution images without aiming, focusing, or calibration

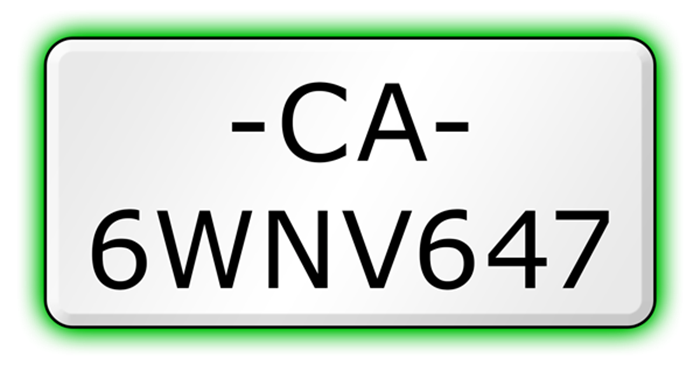

1. Capture license plate

As the vehicle drives through, an image of the vehicle and license plate is captured automatically while in motion. Cameras capture front and rear license plates on every vehicle.

2. Identify characters & locale

License information is determined from the photo. Home state is never assumed.

3. Obtain VIN & specs

Automatically determine vehicle year, make, model and alignment specifications. Internet connection is required, powered by CARFAX™. No monthly subscription fees.

4. Vehicle information shown

Customer's vehicle information and photo is automatically displayed on Flightboard™ and printouts for easily-guided conversations. Alignment angle results are compared against OEM specs.

Automatic body image capture

Prevent false damage claims by capturing 40+ images of every vehicle

Safeguard your operations

Save your store thousands of dollars in false vehicle-damage reports

Quickly review images with HunterNet®

Cameras capture an average of 40 images per vehicle, and the intuitive interface displays vehicle info and date of service

Generate collision repair business

Utilize your own collision repair service or refer customers to an affiliate repair shop.

Intuitive Damage-Cam interface displays vehicle information and date of service. 90-day image storage standard.

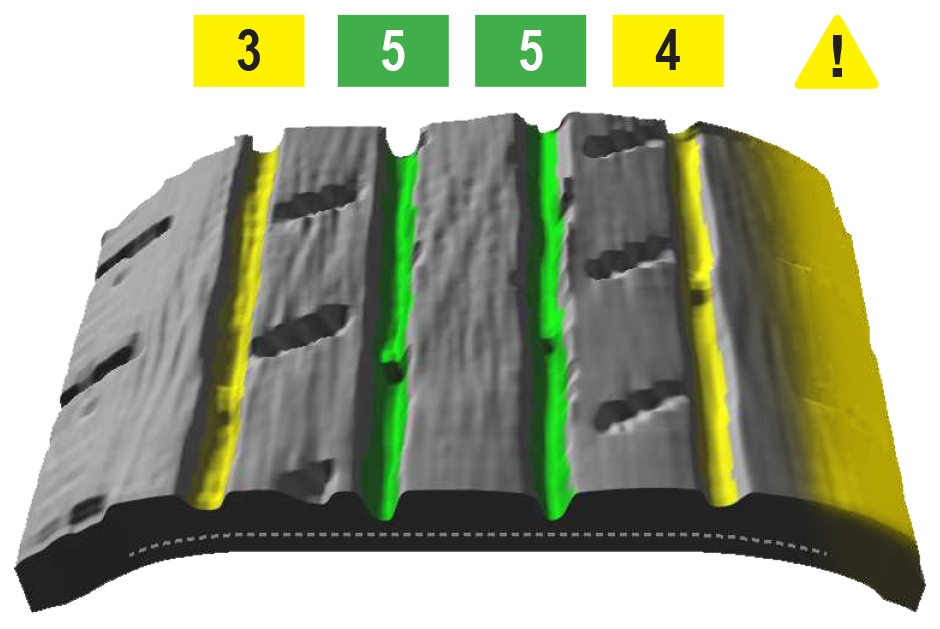

Automatic tire tread measurement

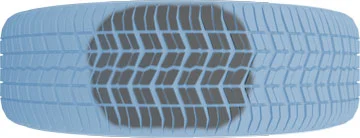

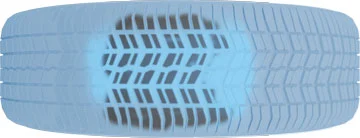

Generate true edge-to-edge 3D models of your customers' tires

Show your customers actual renderings of their tires

Large data sample generates a three-dimensional image of the four-inch testing segment

Precisely measures wet and dirty tires to maximize uptime and opportunities

Color-coded results quickly relay good, marginal or bad tread

Single-line scan measurement can vary greatly

Sipes, wear bars and stones can affect the results of a single-line scan - even scans taken in close proximity to one another.

Basic hand-held measurement is obsolete

Prior to digital measurement technology, tread depth was measured using a handheld, plunger-type measurement tool. This method is time-consuming and error-prone.

Tire tread quality

Inform your customers on critical tire replacement services

Measuring tire tread edge wear is critical to proactive tire safety

A bald tire edge will affect wet weather traction, resulting in longer stopping distances and poor handling.

When a vehicle is moving, the tire's contact patch expands to include the tire's edge

If the edge portion of the contact patch has no tread, it cannot shed water

Most edge wear occurs on the inner edge of the tire and is difficult to detect using the visual inspection methods

How tire tread is affected in wet weather conditions

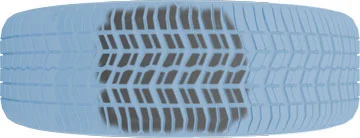

At rest

New tires (10/32")

New tires show clearly defined tread ensuring efficient water displacement.

45 mph

New tires (10/32")

Any tire in motion will lose some contact with the road, but tires with well-defined tread will maintain better contact.

60 mph

New tires (10/32")

At high speeds, even tires with well-defined tread cannot sufficiently displace water. Eventually, only the sides and back of the tire will make contact with the road.

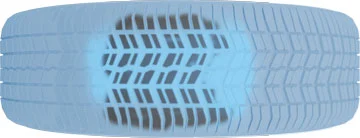

At rest

Marginal tires (4/32")

Worn tires begin to lose tire tread definition, even when stationary.

45 mph

Marginal tires (4/32")

Water displacement efficiency begins to suffer, with pooling at the front of the tire.

60 mph

Marginal tires (4/32")

As speed increases, the worn tire's center has no contact with the road leaving only the sides somewhat in control. This makes for hazardous travel.

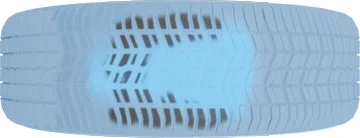

At rest

Critical tires (2/32")

At minimal tread depth, tread definition is barely visible.

45 mph

Critical tires (2/32")

Tires with severely worn tread have far less contact with the road and allow a dangerous amount of water to pool at the front of the tire.

60 mph

Critical tires (2/32")

High speeds are especially dangerous on critical tires. Water can no longer be displaced properly, lifting the tire off the road surface and hydroplaning out of control.

HunterNet® selling tools

Enhance your productivity & revenue

Receive automatic, daily reports

- Automatic, daily performance snapshots by email or text

- View inspection rates and opportunities

- Measure alignment numbers and conversions

- Track balancing and Road Force® utilization

- Achieve big audacious goal

See your service opportunities virtually anywhere, anytime.

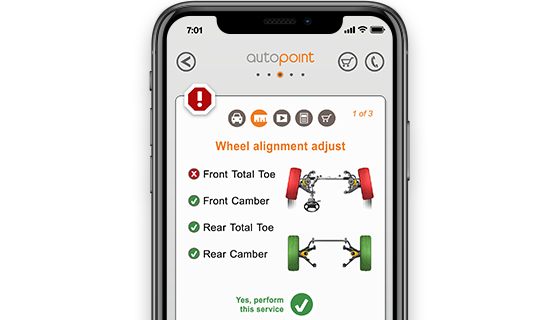

View results automatically to present with your customer. Inform them of needed services with photos & videos. Drive repair authorizations and revenue to new levels.

Measure inspection performance and alignment service opportunities. View trends and pinpoint areas for improvement.

See your service opportunities virtually anywhere, anytime.

![]()

View results automatically to present with your customer. Inform them of needed services with photos & videos. Drive repair authorizations and revenue to new levels.

Measure inspection performance and alignment service opportunities. View trends and pinpoint areas for improvement.

HunterNet® selling tools

Increase customer retention

Enhance the customer intake process

Present results digitally and add services to repair order. Make a tire replacement offer at the vehicle.

Increase technician productivity

Automate electronic multi-point inspection (EMPI) results. Capture photos & videos of actual customer needed repairs.

Deliver results over mobile

Send results to customer via text or email, lets you sell more service to off-site customer on-the-go. Offer self-guided, informative service experience with interactive content so you can sell more services to customers on-the-go.

Connect with your preferred integration partner

Hunter equipment integrates with leading industry partners to span the entire customer service experience, including virtually every major dealer management and shop management system.

Documents

Explore further

Designed & Built in the USA

Family owned, goal-driven

Expert assembly goes into each alignment system, alignment console, tire changer, balancer, brake lathe and other components.

Hunter service

Largest in the industry

Hunter deploys the largest service force of highly-qualified representatives in the industry.

Innovation Team

Award-Winning

Hundreds of patented and exclusive features begin with the research and development team of mechanical, electrical and software engineers.